Elektronikos projektavimas ir gamyba

Projektuojame, programuojame ir gaminame elektronikos gaminius pagal užsakovo reikalavimus. Kuriame įrenginius nuo paprasčiausių buitinių elektronikos prietaisų iki sudėtingų valdiklių skirtų pramonei, medicinai ir energetikai.

Įmonė specilizuojasi naujų elektronikos produktų kūrime ir vystyme (elektronikos R&D). Inovacijų siekiančioms įmonėms kuriame naujus elektronikos produktus. Taip pat teikiame elektronikos surinkimo paslaugas mažoms ir vidutinėms gaminių partijoms.

Atliekame visus gaminio realizavimo procesus: veiklos administravimas, planavimas, projektavimas, gaminio programavimas, gamyba ir patikra, kokybės kontrolė.

Supažindinkite mus su savo problemomis ir mes padėsime rasti optimaliausią sprendimą.

Kompanijos profilis

- Jutikliai su integruota PLC funkcija

- Pramoninių ir buitinių procesų valdymas ir duomenų surinkimas

- Daiktų internetas IoT, valdymas WiFi ZigBee, DALI, ir t.t.

- Objektų skenavimas ToF kameromis

- Rastrinio ir 3D vaizdo duomenų apdorojimas

- Iki 20kw 12w/cm2 LED UV džiovyklos srautinėms gamybos linijoms

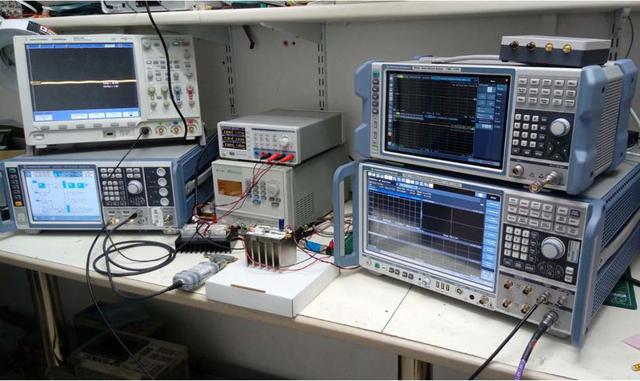

- Pramoninė gaminių testavimo įranga

- Pramoninių ir buitinių procesų valdymas ir duomenų surinkimas

- Daiktų internetas IoT, valdymas WiFi ZigBee, DALI, ir t.t.

- Objektų skenavimas ToF kameromis

- Rastrinio ir 3D vaizdo duomenų apdorojimas

- Iki 20kw 12w/cm2 LED UV džiovyklos srautinėms gamybos linijoms

- Pramoninė gaminių testavimo įranga

Kompanijos veikla

- Įvertinsime produkto sukūrimo galimybes

- Apskaičiuosime sukūrimo ir gamybos kaštus

- Sukursime, pagaminsime ir užprogramuosime elektroninę produkto dalį

- Suprojektuosime ir pagaminsime mechaninę podukto dalį

- Sertifikuosime produktą mūsų partnerių laboratorijose

- Atliksime pilną produkto testavimą

- Paruošime techninę dokumentaciją

- Suteiksime jūsų gaminiui CE sertifikatą

- Apskaičiuosime sukūrimo ir gamybos kaštus

- Sukursime, pagaminsime ir užprogramuosime elektroninę produkto dalį

- Suprojektuosime ir pagaminsime mechaninę podukto dalį

- Sertifikuosime produktą mūsų partnerių laboratorijose

- Atliksime pilną produkto testavimą

- Paruošime techninę dokumentaciją

- Suteiksime jūsų gaminiui CE sertifikatą

Darbo patirtis

- Integruotų OpenWrt, Yocto, Android ir kitų Linux pagrindu veikiančių sistemų ir aplikacijų programavimas

- Mikrovaldiklių ARM, AVR ir mikroprocesorių ARM, MIPS, x86 sistemų projektavimas ir programavimas

- Įėjimo ir išėjimo grandinių bei jų apsaugų projektavimas

- Profesionalaus LED apšvietimo valdymas

- Alkoholio iškvėptame ore matavimas

- Duomenų surinkimas ir apdorojimas ir saugojimas AI DI FFT ir t.t.

- Mikrovaldiklių ARM, AVR ir mikroprocesorių ARM, MIPS, x86 sistemų projektavimas ir programavimas

- Įėjimo ir išėjimo grandinių bei jų apsaugų projektavimas

- Profesionalaus LED apšvietimo valdymas

- Alkoholio iškvėptame ore matavimas

- Duomenų surinkimas ir apdorojimas ir saugojimas AI DI FFT ir t.t.

Viskas nuo idėjos iki galutinio produkto !